Mineral Processing Aids

Optimizing Your Mineral Processing Operation

Nalco Water is a global leader in mineral processing reagents and solutions. We have decades of experience across a variety of markets and more than 1,600 global research, development and engineering associates. Our global reach and expertise helps us deliver technical, economic and environmentally sustainable mineral processing solutions from mine to mill.

Our diverse portfolio of mineral processing aids spans a variety of applications and includes rheology modifiers, filter aids, crystal growth modifiers, liquor stabilizers, oxalate stabilizers and reagents for humate removal. By solving for mining process optimization, Nalco Water can help you maximise productivity, improve throughput and positively impact your bottom line.

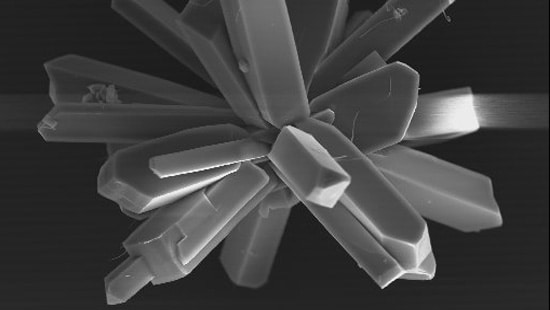

In the Spotlight: Crystal Growth Modifiers

In the competitive environment of alumina refining, processing plants are continuously challenged to increase yield while maintaining hydrate crystal size and quality. Nalco Water offers crystal growth modifier (CGM) programmes that are specifically designed for use within the precipitation circuits of the Bayer process. The programmes provide additional control of agglomeration and nucleation mechanisms, which can positively impact final product size control, liquor yield, hydrate classification and oxalate interference control.

CGMs are just one of Nalco Water's comprehensive portfolio of mineral processing aids. Contact us to discuss your specific operational needs and learn more about our mineral processing solutions.

Flotation 360™

Mineral processing optimization can feel like a moving target. Changing ore, an incorrect formulation or failing to balance recovery and grade can impact your bottom line. But Nalco Water has your solution: Flotation 360. This digital technology helps you maximise productivity and optimise your flotation circuit performance.

Optimise your circuit with the predictive capabilities of Flotation 360 to help:

- Improve performance to increase recovery and profitability

- Enhance visibility of potential impacts of future ore changes, allowing for mitigation of any challenges in advance

- Optimise reagent dosing and chemical consumption, improving the total cost of operations

- Reduce maintenance challenges such as float cell valve failures, and spend less time manually troubleshooting

Mineral Processing Aids Success Stories

Crystal Growth Modifiers Programme Drives Improvements in Efficiency, Sustainability, Performance and Cost at Alumina Plant

At a Mediterranean-based alumina plant, corporate social responsibility played a strong role in its daily operations. With a focus on safety, optimal resource use and minimized costs, the plant sought new and effective methods to improve overall process efficiency. In partnering with the plant, Nalco Water determined that applying a crystal growth modifier could help drive the results that the plant needed.

Download the case study to learn how Nalco Water's crystal growth modifier programme helped to generate a value of more than €743,000 per year in increased profitability and savings.

Driving Innovation in Global Mineral Processing

Nalco Water places great emphasis on research, development and innovation. In our commitment to addressing mineral processing challenges, we have assembled dedicated teams of chemists and engineers to drive our customer-focused technical research centres around the globe. From the United States to western Australia, the Netherlands to western India and everywhere in between, Nalco Water offers a globally connected team of experts that are local to your plant and keenly aware of the regionalized challenges that can impact your operations.

Nalco Water Mineral Processing Aids

This dispersant is an aqueous formulation of low molecular weight specially designed to be an effective dispersant and antiscalant in mineral processing applications where high lime circuits are operated. The dispersant functions by lowering the viscosity of mineral slurries. It can also modify crystal formation and thereby alter the nature and rate of scale deposition.

- Improves slurry rheology.

- Cleans minerals surfaces leading to improved recovery of valuable minerals.

- Reduces the rate of scale deposition where scaling problems are prevalent.

- Prevents slime coating on valuable minerals.

- Non-foaming properties.

- Stable at high temperatures.

| Products |

|---|

| NALFLOTE 600-05 |

The Filtermax dewatering aids are principally used to aid in the filtration of mineral concentrates in order to reduce filter cake moisture and improve filter cake handling characteristics. They function by lowering the surface tension of water and more importantly, by making the mineral particle surfaces more hydrophobic (water repellent), thus allowing for higher levels of moisture reduction.

- Lower cake moisture that reduces drying and freight costs.

- Faster filtration rates thus lowering capital investment in filters.

- Better cake release increasing the efficiency of the filters.

- Reduces filter cloth blinding improving the life of the cloth.

| Products |

|---|

| FILTERMAX 470LV |

| FILTERMAX 440GFM |

Programmes, Products, Equipment and Services

Explore our Mineral Processing Aid Offerings

We couldn't find any results for "".