Craft Brew Programme

Partner with the experts at Ecolab to keep your brewery on the leading edge of quality, safety, efficiency and sustainability. Ecolab’s integrated brewery cleaning and sanitation programme helps improve and simplify brewhouse cleaning processes and systems to save you time and help producing consistent results every time.

Summit Brewing Testimonial

_

CIP Optimization of Your Brewery Cellar Through Use of Mixed-Peracids in Cold Sanitation & Washes

A hot water sanitizing step requires energy, time, and a cool-down rinse step that can largely be saved by employing a cold-sanitizing process for the CIP of the cellar vessels. Ecolab Technical Support Specialist Michael Doseger explains the substantial benefits of implementing a cold wash CIP process and leveraging Synergex™ for the cellar-side vessels of brewery operations.

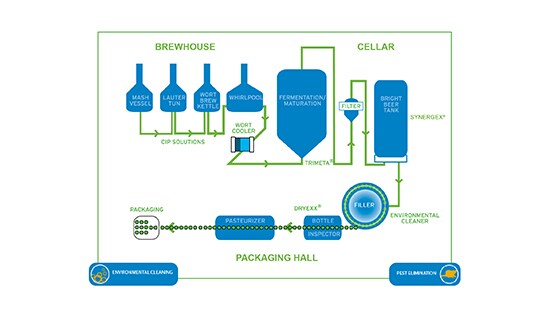

Comprehensive Brewery Sanitation and Water Solutions

As the industry leader in cleaning and sanitation solutions with a depth of brewery experience, we help optimise brewing operations, support exceptional beer quality and empower your team to work smart and safe.

Synergex™ in Craft Brew

Synergex™ is a U.S. EPA-registered*, mixed-peracid (PSOA) based sanitizer and disinfectant that helps improve product quality and food safety while maximising productivity across your brewery and can also be used as a cleaner. Designed for brewery cleaning use in:

• Bright beer tanks (BBTs)

• Filler CIPs

Increase Productivity

- Reduce conventional 4 or 5 step CIP washes with Synergex™ as a 3-step cold wash detergent, using a pre-rinse, wash and post-rinse process

- Customers have seen a shortened cleaning period when washing under CO2, eliminating the need for CO2 to be exhausted from the system after each cleaning cycle

Improve Product Quality

- Reduce day-to-day variability and eliminate product to product flavor carry over

- Control and verify usage with conductivity and in-line monitoring

- Penetrate biofilms, killing 99.9999% of Listeria monocytogenes and Pseudomonas aeruginosa pathogens on hard, non-porous food contact surfaces, with no-rinse options when used as a sanitizer (at minimum temperature 33 degrees C or 91 degrees F)

Minimise Environmental Impacts

- Significant energy savings from cold washing, no need to heat the solution

- Ability to wash under CO2 pressure as an acid eliminates need to exhaust CO2 from your BBT

- No-phosphorus formulation helps minimise phosphate-related effluent fees

Resources

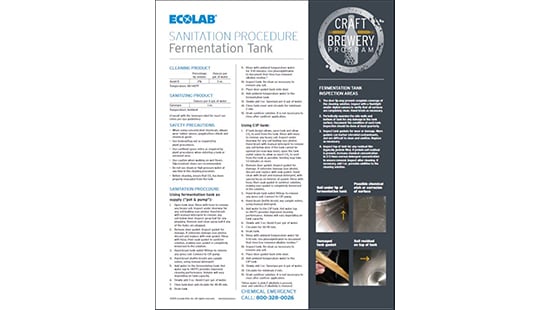

Cleaning and Sanitizing Procedures

This is one area where you don’t have to develop your own recipe from scratch. We’ve got proven procedures to help ensure a clean and sanitized operation with every batch.

Available Sanitation Procedures:

- Mash Tank

- Lauter Tun

- Brew Kettle

- Fermentation/Maturation Tank

- Aging and Bright Beer Tanks

- Kegs

- Heat Exchanger

- Parts Cleaning and Soak

- Environmental Cleaning

For additional information, contact your sales representative or use the Contact Us form.

Training

In an operation like yours, everyone wears multiple hats. Luckily, we’ve got your back. From sanitization advances to food safety updates, we continue brewing up training programmes to help keep you and your team up to speed.

Available Training:

- Chemical Safety

- Brewery Sanitation Basics

- Brewhouse Sanitization

- Brewery Cellar Sanitization

- Brewery Packaging

- Hall Sanitization

- Brewery CIP

For additional information, please contact your sales representative or use the Contact Us form.

Your Partner in Perfection

World Class Service

Safety at Your Brewery Matters