Conveyor Lubrication Solutions

Keeping your food and beverage supply moving is a big task. Traditional conveyor lubricants for food and beverage processing can mean high water usage, continuous applications and extensive scheduled downtime. We have better ways to improve your supply movement.

Ecolab has the chemistry, service, equipment and expertise needed to keep your conveyor production lines running optimally. Conveyor lubricant system recommendations will depend upon conveyor and packaging types. Our DryExx™ dry lubrication systems are silicone-based and can reduce lube system water use by up to 97%.

We can help you keep your lines running smoothly while cutting the amount of water you need, improving your efficiency and reducing bottle tipping. Discover what Ecolab can offer your conveyor lubrication system.

Programmes, Products, Equipment and Services

Explore our Conveyor Lubrication Offerings

We couldn't find any results for "".

Equipment & Engineering Services

As the company that invented clean-in-place, our experienced, full-service team has the knowledge, technology and industry expertise to deliver systems designed to help reduce overall operational costs and enhance food safety programmes.

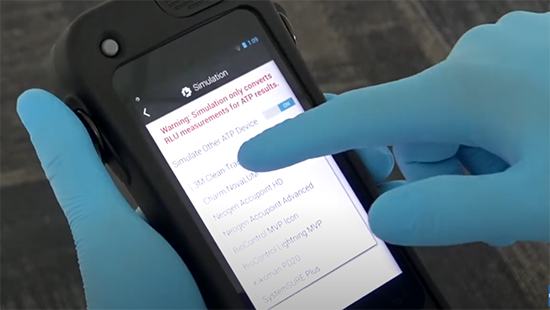

Hygiene Monitoring Programme

Ecolab partners with Hygiena to bring the food and beverage industry a new hygiene monitoring programme that creates a best-in-class, innovative and cost-competitive offering that helps optimise your food safety programme.

Food Safety Training

The Ecolab Food Safety Institute provides classroom and hands-on industry and customer training courses that help to proactively manage food safety risks, improve productivity and help assure regulatory compliance.

Food Safety Expertise

As the global leader in food safety technology, Ecolab provides accessible, actionable food safety information to our customers across the food supply chain, including quick customer response to food safety concerns.