Supporting Asia's Data Centre Growth with Sustainable Water Use

DATA centre growth in asia pacific

Asia Pacific’s data centre service market is expected to grow by 27% per annum and is set to exceed the European market by 2021, according PwC’s Surfing the Data Wave report. In September, Facebook announced it was investing US$1 billion to build its first data centre in Asia. Google also recently announced it was investing US$850 million to expand its Singapore data centres to meet demand stemming from mobile growth, e-commerce and cloud computing. As demand for data centre surges in the region, the need for solutions to keep data centres cool is also on the rise.

“Water is a nontoxic and safe resource that has excellent heat transfer properties, making it an ideal medium for cooling applications,” said Vishal Sharma, senior vice president and general manager, Nalco Water Asia Pacific, Ecolab. “Having said that, the challenges of water availability in many parts of the planet make it a necessity for good water management to minimise consumption and maximise reuse and recycling.”

“The challenges of water availability in many parts of the planet make it a necessity for good water management to minimise consumption and maximise reuse and recycling.” - Vishal Sharma, senior vice president and general manager, Nalco Water Asia Pacific, Ecolab.

Data centre cooling system

A typical data centre cooling system uses up to 30 million liters of water a year per megawatt of electricity, according to the Uptime Institute, an organisation focused on improving the performance, efficiency, and reliability of business-critical infrastructure. On average 74.6 million liters of water are used annually per 1,000 tons of cooling.

TRIPLE Threat

While water is the preferred method for keeping data centres at the ideal temperature, it’s not perfect. Chilled water-cooling systems face three common challenges: corrosion, bio-fouling and scale.

“Countries in the APAC region have different water qualities, so the challenges vary,” Sharma said. “In tropical areas, corrosion and biofouling are typically major concerns, which is why treating the water is vital to optimizing the chilled water-cooling systems’ performance.”

For data centres, corrosion, biofouling and scaling in water could lead to an increase in operating costs. For example, a scale of 0.3 mm, the same thickness as egg shells, on a chilled water-cooling system results in 21% loss in heat transfer. For a 1,200-ton chilled water-cooling system, that’s equal to US$16,000 in additional energy consumption per year.

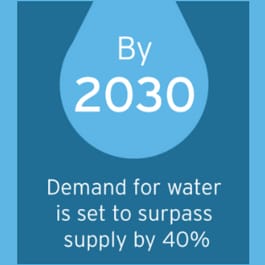

Properly treating water is also vital to protecting this precious resource — by 2030, the demand for water is set to surpass supply by 40%. To address the growing gap between demand and supply, Ecolab offers a wide range of solutions that remove impurities and allow companies to recycle wastewater or improve water quality for use in chilled water-cooling systems.

Bespoke solutions

Different water qualities require different treatments. To help organizations save water and improve efficiency, Ecolab offers 3D TRASAR™ Technology for Cooling Water, an automated sustainable water treatment system that remotely monitors, reports and suggests chemicals and equipment to optimise cooling systems.3D TRASAR™ Technology for Cooling Water uses connected sensors, controller units and gateways to collect and send real-time data on conductivity, pH levels, turbidity, flow rates, corrosion, biofouling and scaling potential.

"There are probes in the water stream that are collecting data, to the tune of about 48 billion data points a year that we collect across 40,000 systems we've deployed at customer sites," said Vishal Sharma, Senior Vice President & General Manager, Nalco Water Asia Pacific, Ecolab.

Using the data collected, Ecolab engineers provide 24/7, year-round remote monitoring to determine the best water treatment chemicals and equipment for optimum cooling system performance. Ecolab also provides on-site technical support to address any evolving needs. Ecolab launched 3D TRASAR in 2004 and its technology stems from the TRASAR Technology launched in 1988.

Diverse offerings

3D TRASAR technology offers water treatment solutions for corrosion, biofouling and scaling such as:

- White-Rust Inhibitor — to minimise white rust corrosion that affects galvanized or zinc surfaces. The product is a synergistic blend of passivation agents, inhibitors and dispersing agents.

- STA-BR-EX®, ControlBrom®, and ACTIBROM® — to reduce the amount of oxidizing biocide required to control microbiological activity in cooling water.

Environmental Hygiene Services — to provide specialized services that help control private and public health risks such as Legionella.

“Ecolab touches 1.5 billion digital users daily with our worldwide water treatment programme,” Sharma said. “Globally, Ecolab’s cooling water technologies combined saved 146 billion gallons of water in 2017 — equivalent to the yearly drinking water needs of more than 505 million people.”

Related Stories

Visitors who viewed this story also viewed