Inlet Integrity Programme

Protecting Your Process

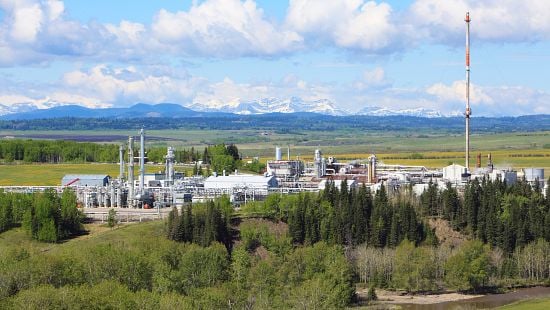

Whether iron sulfide or other foulants are within the incoming gas stream, the Inlet Integrity Programme can help effectively extract what’s harmful to a plant’s efficient processing. Nalco Water offers a comprehensive approach to help midstream plants achieve greater reliability and processing efficiency at a lower operating cost.

Innovative Chemistries Offer Maximum Protection

The Inlet Integrity Programme features two chemistries that can be used together or separately, depending on the situation.

- Iron Sulfide Inhibitor and Corrosion Protection is patented chemistry that helps minimise iron sulfide formation and corrosion, and remove existing deposits.

- Inlet Separator Solid Removal Enhancement helps effectively remove suspended solids to significantly minimise the potential for foulants to move through the process.

Consult with a Nalco Water representative to develop a customized treatment programme for the inlet separator.

Discover the eROI Benefits

Asset Protection

Maintain plant operations at design capacity by helping to protect assets from the damaging effect of foulants in the incoming gas stream.

Reliability

Proactively protect a plant from performance issues throughout the entire process, particularly the compressors and amine unit.

Productivity

Minimise instabilities, disruption and expense by avoiding significant costs associated with manual maintenance, downtime and repairs of the inlet separator and other equipment.

Technical Article

Transforming Inlet Separator Performance

Featured in Hydrocarbon Engineering, May 2025

Discover how Nalco Water’s Inlet Integrity Programme helps gas processors proactively tackle fouling, streamline maintenance, and enhance operational reliability. Explore case studies with measurable results and gain practical insights to optimise inlet separator performance.

Customer Success Story

Inlet Integrity Programme Protects Assets and Delivers Value

A gas processing plant focused on inlet separator treatment to reduce a daily hot valve problem and saved nearly $310K.

Moving Midstream Forward with Outcome-Based Solutions for Inlet Separator Treatment

The Inlet Integrity Programme from Nalco Water offers a proactive approach and expert, individualized problem-solving to deliver optimal results.

In addition to innovative chemistries and deep technical expertise, we provide services and data reporting that are tailored to the key business drivers and unique needs of each plant.

Fill out the form or contact your Nalco Water representative for details or to schedule an appointment.

_

_